Chlorinated Paraffins (CPs) are widely used as extreme pressure modifiers for cutting fluids. While CPs work very well as an extreme pressure modifier, there have been examinations from the Environmental Protection Agency (EPA) to understand toxicity levels. In this article, we take a closer look at how chlorinated paraffins are used in lubricants and what to consider when deciding whether to implement a chlorinated paraffin-based lubricant in your system.

What are chlorinated paraffins and how are they used in lubricants?

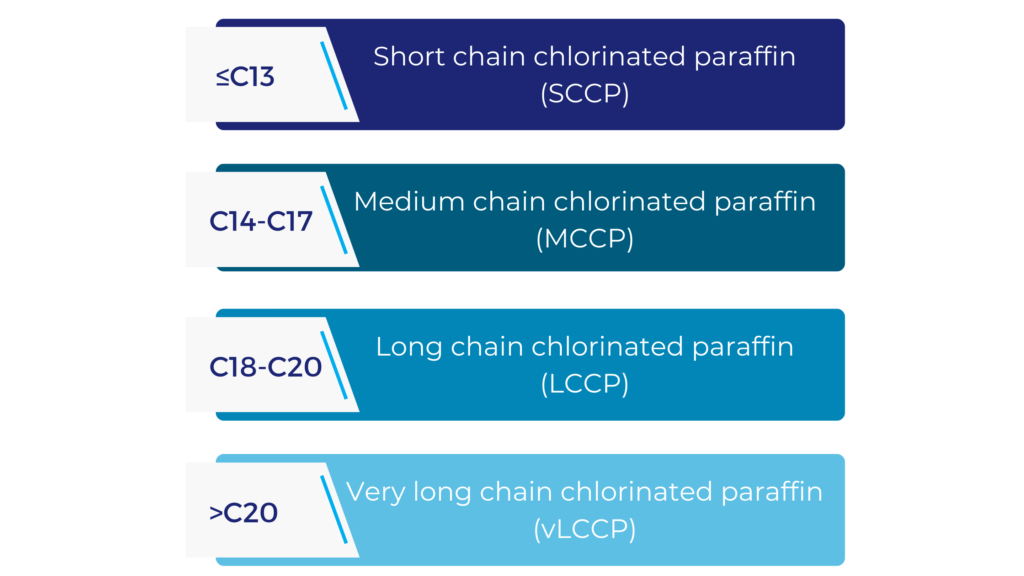

Chlorinated Paraffins, also referred to as polychlorinated n-alkane, are a broad chemical category of synthetic carbon-chain compounds with various degrees of chlorination. The chain lengths of commercial paraffin products vary but the most common are C10-C38. Further defining chlorinated paraffins is often done based on the carbon chain length:

The purpose of chlorinated paraffins in a lubricant is to impart characteristics of enhanced surface protection in extreme pressure conditions. CPs are a valuable tool in a formulator’s toolkit due to the advantages in extreme pressure performance at an optimized cost.

Considerations when using lubricants with chlorinated paraffins

When choosing between CP-based and non-CP-based lubricants for your operation, look beyond the up-front efficiency and consider the following:

- What is the carbon chain length of the chlorinated paraffin?

- Are there any regulations for the lubricant additives? *

- Will this product conflict with the sustainability guidelines my organization has in place?

- Will I need to adjust the waste removal process to accommodate for this product?

Your answers to those questions will help you determine what lubricant will work best for your company.

* There are different hazards and environmental restrictions based on the carbon chain length. Reference the EPA Risk Management for Short-Chain Chlorinated Paraffins guide for more information.

The future of chlorinated paraffins in U.S. Lubricants products

While U.S. Lubricants maintains legacy formulations that contain medium, long, and very long chain CPs, our comprehensive product offering focuses on utilizing CP alternative technology. U.S. Lubricants has many mainline Shearglide® and Aquaglide metalworking fluids which are formulated without chlorine to align with your organization’s sustainability and environmental policies. As advancements in CP replacement technologies progress, U.S. Lubricants continues to integrate strong, cost-effective additive solutions into our products to drive success in metalworking applications. By using CP alternatives, such as phosphate and polymeric esters, the result is fewer environmental health and safety concerns in comparison to CPs.

Our team is ready to help you navigate finding the right metalworking lubricants for your operation – contact us today to learn how we can customize a solution for your unique business needs.